As mentioned on our Maximum Allowable Quantities (MAQs), Control Areas, and Approved Storage webpages, there are a number of specifications that affect the total MAQs for any given control area and laboratory suite. In addition to floor level, fire-resistance rating of fire barriers that surround the space(s), and approved storage methods, a number of other specifications must be considered that determine MAQs:

Exhausted enclosures are suitable for gases (inert, flammable, oxidizing, reactive, pyrophoric, toxic, highly toxic, or corrosive). They are not designed for cryogenic fluids.

Types – Exhausted enclosures include gas cabinets, fume hoods, and similar equipment designed to contain and remove gases, fumes, vapors, and mists at the source. General ventilation in rooms or areas does not qualify as an exhausted enclosure.

Ventilation – Exhausted enclosures must have a dedicated exhaust ventilation system. This system should maintain negative pressure relative to the surrounding area and must be installed according to the New York State Mechanical Code.

Ventilation systems used for highly toxic and toxic gases shall also comply with the following:

- The average ventilation velocity at the face of the enclosure shall be not less than 200 feet per minute (1.02 m/s) with not less than 150 feet per minute (0.76 m/s).

- Exhausted enclosures shall be connected to an exhaust system.

- Exhausted enclosures shall not be used as the sole means of exhaust for any room or area.

Determining Floor Level

To determine the floor level for a control area or laboratory suite, the definition of grade plane must be examined:

Grade plane – A reference plane representing the average of finished ground level adjoining the building at exterior walls. Where the finished ground level slopes away from the exterior walls, the reference plane shall be established by the lowest points within the area between the building and the lot line or, where the lot line is more than 6 feet (1829 mm) from the building, between the building and a point 6 feet (1829 mm) from the building.

Story above grade plane – Any story having its finished floor surface entirely above grade plane, or in which the finished surface of the next floor above is:

- More than 6 feet (1829 mm) above grade plane, or

- More than 12 feet (3658 mm) above the finished ground level at any point.

Floor level is highly important for determining:

- MAQ's

- Number of control areas or laboratory suites allowed per floor

- The fire-resistance rating of fire barriers surrounding each control area or laboratory suite

Design and Number of Control Areas and Laboratory Suites per floor

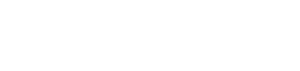

Design and Number of Control Area Per Floor Table:

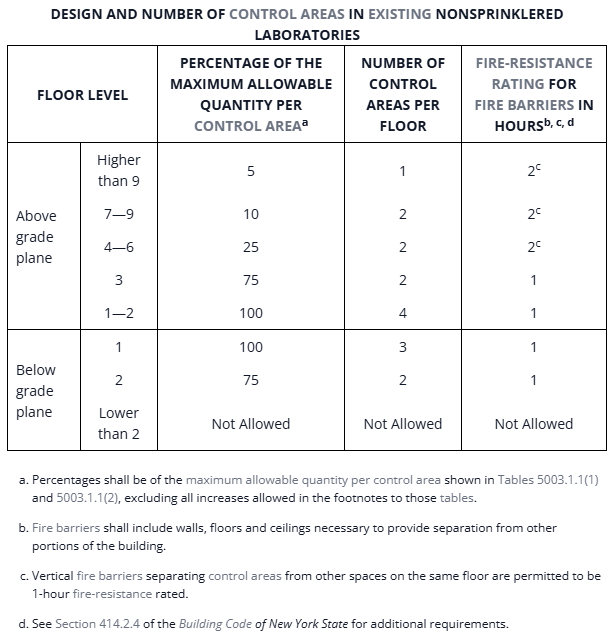

Design and Number of Laboratory Suites Per Floor Table:

Buildings equipped with automatic fire suppression systems, such as sprinklers or approved non-water alternatives, offer increased life safety. These systems are designed to control fires long enough to allow safe evacuation.

For example, in a five-story building, a fire on the third floor could quickly spread to upper floors and nearby rooms, filling them with smoke and fire and making evacuation difficult. A full sprinkler system can contain the fire to the room where it started, allowing safe evacuation from surrounding areas—especially when combined with fire-resistant construction in corridors and other critical areas.

Because sprinkler systems significantly enhance life safety, buildings with full sprinkler coverage are often allowed to store higher quantities of hazardous materials. For instance, in most occupancy types, the maximum allowable quantity (MAQ) of flammable liquids can be doubled in fully sprinklered buildings.

Mechanical Ventilation in Laboratories

Mechanical ventilation is essential for maintaining safety in laboratory spaces. Depending on the types of chemicals stored, handled, or used, a lab may require both general and hazardous exhaust systems.

General Exhaust – This refers to overall room ventilation and is typically higher in laboratories than in non-lab areas like offices. A typical lab should have 4–6 air changes per hour or about 1 CFM (cubic foot per minute) per square foot of space. This helps remove hazardous vapors or gases and replaces them with clean air.

Hazardous Exhaust – Labs that use or dispense toxic, flammable, corrosive, or reactive materials often rely on fume hoods or gas cabinets to capture and remove dangerous vapors. Hazardous exhaust is separate from general exhaust and is not recirculated; it is vented directly outside. Some materials, like concentrated perchloric acid, require specially designed hoods. Highly toxic gases must be stored in gas cabinets or similar exhausted enclosures.

Occupancy classification refers to the formal designation of the primary purpose of the building, structure or portion thereof. These classifications are based on the nature of the hazards and risks to building occupants generally associated with the intended purpose of the building or structure.

Occupancy Classifications in New York State codes include:

- Assembly: Group A (i.e. lecture halls, auditoriums, EMPAC, Folsom library, Houston Field House)

- Business: Group B (i.e. offices, higher education buildings, laboratories)

- Educational: Group E (i.e. school or space used for educational purposes through 12th grade)

- Factory Industrial: Group F (i.e. metal or wood shops, photographic film development studios)

- High Hazard: Group H (i.e. chemical stock rooms, flammable liquid dispensing rooms, semiconductor fabrication rooms, spaces where MAQ's for traditional occupancies are exceeded)

- Institutional: Group I (i.e. hospitals, correctional centers, nursing homes)

- Mercantile: Group M (i.e. markets and retail stores)

- Residential: Group R (i.e. dormitories, apartments, fraternities and sororities)

- Storage: Group S (i.e. dedicated storage of non-hazardous materials)

- Utility and Miscellaneous: Group U (i.e. agricultural buildings, private garages, greenhouses)

A number of these occupancies exist at the Institute, with the majority of spaces falling under Groups A, B, and R.

Occupancy classification is an important factor in MAQ limitations. For example, Group H occupancies are constructed to account for certain types of hazardous materials and/or quantities of hazardous materials that exceed MAQs.

The physical state of a chemical, solid, liquid, or gas, can significantly impact its hazard level. For example, gases are more difficult to contain during a leak, therefore stricter regulations apply to certain types, such as toxic, pyrophoric, and flammable gases. NYS Fire Code addresses materials based on their physical state.

Storage of hazardous materials is defined and used in multiple ways in NYS Fire Code.

Definitions:

- Storage, Hazardous Materials – The keeping, retention or leaving of hazardous materials in closed containers, tanks, cylinders, or similar vessels; or vessels supplying operations through closed connections to the vessel.

- Closed container – A container sealed by means of a lid or other device such that liquid, vapor or dusts will not escape from it under ordinary conditions of use or handling.

- Use (Material) – Placing a material into action, including solids, liquids and gases.

- Closed system – The use of a solid or liquid hazardous material involving a closed vessel or system that remains closed during normal operations where vapors emitted by the product are not liberated outside of the vessel or system and the product is not exposed to the atmosphere during normal operations; and all uses of compressed gases. Examples of closed systems for solids and liquids include product conveyed through a piping system into a closed vessel, system or piece of equipment.

- Open system – The use of a solid or liquid hazardous material involving a vessel or system that is continuously open to the atmosphere during normal operations and where vapors are liberated, or the product is exposed to the atmosphere during normal operations. Examples of open systems for solids and liquids include dispensing from or into open beakers or containers, dip tank and plating tank operations.

For hazardous materials, there is a notable difference in MAQs for chemicals in storage vs. in use.

Storage

In Use - Closed

In Use - Open

Each hazardous chemical has specific physical and health risks, and some may have multiple hazards. For example, acetic acid is both flammable and corrosive.

Maximum Allowable Quantities (MAQs) are the total amount of hazardous materials allowed per hazard class and physical state within a single control area. MAQ limits vary by control area or laboratory suite and depend on building features such as floor level and the presence of automatic fire sprinklers.