Properly storing hazardous materials plays an important role in managing the maximum allowable quantities (MAQ) for a control area. Hazardous materials that are stored in approved storage cabinets, day boxes, gas cabinets, gas rooms, exhausted enclosures or in listed safety cans may increase MAQs for certain hazard categories. Additionally, highly toxic gases are not permitted in any quantity unless they are stored within approved gas cabinets or exhausted enclosures.

Note: Per New York State (NYS) Fire Code, flammable storage cabinets must be self-closing and be equipped with a 3-point latching system. There are many cabinets available commercially that close manually and are not considered approved in NYS.

Gas cabinets are exhausted enclosures suitable for gases (inert, flammable, oxidizing, reactive, pyrophoric, toxic, highly toxic, or corrosive). They are not designed for cryogenic fluids.

Ventilation – Gas cabinets shall be provided with an exhaust ventilation system. The ventilation system shall be designed to operate at a negative pressure in relation to the surrounding area and shall be installed in accordance with the NYS Mechanical Code. Gas cabinets shall also comply with the following:

- Ventilation systems used for highly toxic and toxic gases shall also comply with the following:

- The average ventilation velocity at the face of the enclosure shall be not less than 200 feet per minute (1.02 m/s) with not less than 150 feet per minute (0.76 m/s).

- Exhausted enclosures shall be connected to an exhaust system.

- Exhausted enclosures shall not be used as the sole means of exhaust for any room or area.

Maximum number of cylinders per gas cabinet. The number of cylinders contained in a single gas cabinet shall not exceed three. (Note: for toxic and highly toxic gases, there is an exception for cabinets containing cylinders not exceeding one pound (0.454 kg) where net contents are allowed to contain up to 100 cylinders).

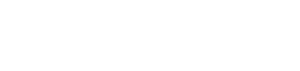

Flammable storage cabinets must be used for storing flammable and combustible liquids.

Design and Construction – Flammable storage cabinets must be in accordance with the following:

Materials – Cabinets shall be listed in accordance with UL 1275, or constructed of approved wood or metal in accordance with the following:

- Unlisted metal cabinets shall be constructed of steel having a thickness of not less than 0.044 inch (1.12 mm) (18 gage). The cabinet, including the door, shall be double walled with 1 ½-inch (38 mm) airspace between thew walls. Joints shall be riveted or welded and shall be tight fitting.

- Unlisted wooden cabinets, including doors, shall be constructed of not less than 1-inch (25 mm) exterior grade plywood. Joints shall be rabbeted and shall be fastened in two directions with wood screws. Door hinges shall be of steel or brass. Cabinets shall be painted with an intumescent-type paint.

Labeling – Cabinets shall be provided with a conspicuous label in red letters on contrasting background that reads: “FLAMMABLE – KEEP FIRE AWAY.”

Doors – Doors shall be well fitted, self-closing and equipped with a three-point latch.

Bottom – The bottom of the cabinet shall be liquid tight to a height of 2 inches (51 mm).

Capacity – The combined total quantity of flammable and combustible liquids in a cabinet shall not exceed 120 gallons (454 L).

Approved flammable storage cabinets may either be built into counters as seen in the image within the Exhausted Enclosures section of the Specifications that Affect MAQ's page or stand alone units similar to the one below.

Safety cans shall be listed in accordance with UL 30 where used to increase maximum allowable quantities per control area of flammable or combustible liquids in accordance with the MAQ Table.

There are two types of safety cans, Type 1 and Type 2.

Type I safety cans have one opening. You use that opening to fill the can and dispense/pour fuels. There are no other openings or vents, so type I cans can get gulpy if poured too hard. They are intended to pour fuel into vessels with big openings.

Manufacturers have funnel attachments for Type I cans, giving them more accuracy for filling vessels with smaller openings. Some funnel attachments are rigid, while others have bendable hoses.

Type II safety cans have two openings. The filling opening is the same as the type I opening, and the dispensing opening is a permanently attached bendable hose. This makes type II cans very easy to use for filling up vessels with small openings, like lawn equipment or cars.

Some manufacturers also have a release trigger that automatically opens the fill spout while pouring, creating a vent, and allowing a smooth pour. The release trigger is also designed to regulate the flow. Unlike with most gas cans where you need to tip the can more or less to get faster or slower flow, type II cans allow you to control that with the trigger. When the vessel is full, you release the trigger, the flow stops and now you can safely remove the hose without spilling any liquid.

The metal hose is also designed to dissipate static electricity when it comes in contact with a surface. The overall safety and convenience of a type II can is hard to beat.

As seen below, safety cans are color coded to match the material that they are holding:

- Red - Gasoline

- Yellow - Diesel

- Blue - Kerosene

Green - Oil