The safe storage of hazardous chemicals is an essential part of laboratory safety. Chemical storage is complex—there is no one-size-fits-all plan to store chemicals—but there are regulations, campus requirements, and best practices that can guide the process. The general concept is to prevent chemicals from causing harm to people, property, other chemicals, or the environment.

In order to fully understand the hazards associated with stored chemicals you first need to know what chemicals are being stored. Safe storage begins with an up-to-date inventory of chemicals and knowledge of the hazards posed by each chemical

The primary objective when storing chemicals is to minimize the physical and chemical hazards associated with certain chemicals and with the accidental mixing of chemicals due to a laboratory incident. Assessment of these hazards must also consider the mixing of fugitive vapors from volatile compounds which can lead to destruction of containment vessels or potentially explosive conditions.

The first source for chemical-specific information should be the labels and safety data sheets (SDSs) from the manufacturer. You may also contact EHS with questions on chemical safety.

- All chemicals must be stored in a safe, secure location.

- Shelves should be level, stable, and secured to the wall or another stable location. Shelves must have a shelf lip to prevent chemicals from falling off the shelf.

- Store chemicals away from direct sunlight, sources of heat, and egress pathways.

- Hazardous chemicals should be stored below eye level.

- Chemicals should not be stored on the floor, window ledges, or balconies.

- Keep containers closed unless you are dispensing a chemical or adding to the container.

- Provide secondary containment for liquids whenever possible. Secondary containment should be compatible with the containers being stored within. Polypropylene containers are a good universal material.

- Don’t store chemicals in a sink, below the sink, or fume hood. Certain toxic gases that are so dangerous they can only be stored in a gas cabinet or fume hood are the exception.

- Label containers, and be sure container is compatible with the chemicals.

- Use rated storage cabinets or safety cans whenever possible - required for >10 gal. of flammables.

- Cold rooms, refrigerators, and freezers have additional requirements, particularly for flammables.

As a general rule, chemicals need to be physically segregated from incompatible chemicals; some key requirements are listed below.

- Store flammable liquids in approved safety containers in a flammable cabinet. Do not store anything but flammable or combustible liquids in the cabinet.

- Segregate acids from bases.

- Keep oxidizers away from flammables and combustibles.

- Keep corrosives away from substances that they may react with and release corrosive, toxic, or flammable vapors.

- Do not store chemicals alphabetically unless they are compatible.

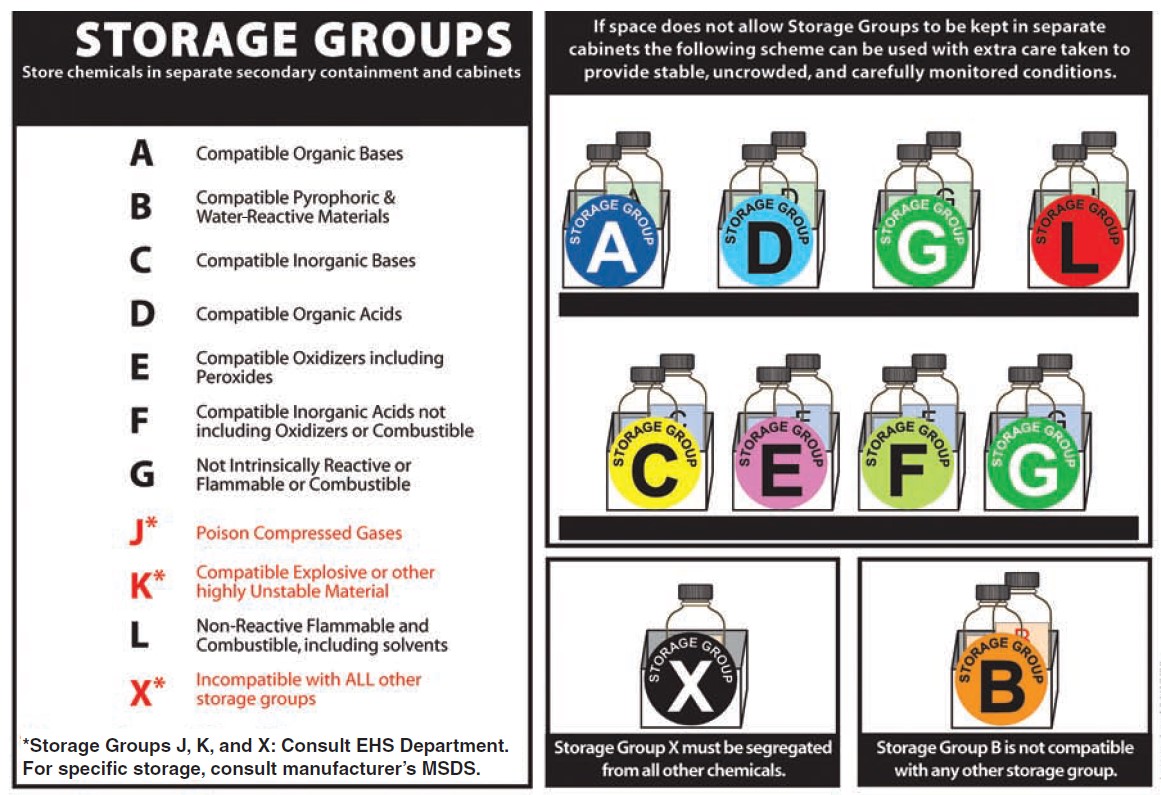

It is prudent to store containers of incompatible chemicals separately. Separation of incompatibles will reduce the risk of mixing in case of accidental breakage, fire, earthquake, or response to a laboratory emergency. Even when containers are tightly closed, fugitive vapors can cause incompatibility reactions that degrade labels, shelves, cabinets, and containers themselves. The table below shows the detailed classification system for the storage of groups of chemicals by compatibility here at Rensselaer.

The system classifies chemicals into 11 storage groups. Each group should be separated by secondary containment (e.g., plastic trays) or, ideally, stored in its own storage cabinet. According to this system, it is most important to separate storage groups B (compatible pyrophoric and water-reactive chemicals) and X (incompatible with all other storage groups). These two groups merit their own storage cabinets.

SOURCE: Prudent Practices in the Laboratory, Adapted from Stanford University’s Chem Tracker Storage System. Used with permission from Lawrence M. Gibbs, Stanford University.

Many chemicals belong to more than one chemical family or hazard class. In many cases, chemicals need to be evaluated on a case-by-case basis. Ideally, guidelines for each category should be observed, but this may not be possible in all instances.

One strategy is to prioritize the hazards of a specific chemical. The hazards should be prioritized from most severe to least. A pyrophoric chemical, for example, may also be a flammable liquid, but the pyrophoric property should outweigh the flammability for storage purposes.

Glacial acetic acid is a common example, as it is both a corrosive acid and a combustible liquid. It should be stored away from corrosive bases, such as sodium hydroxide, and also from oxidizing acids, such as nitric acid. Storing acetic acid in a flammable storage cabinet would be appropriate, prioritizing the combustibility over the corrosivity. If flammable storage space is at a premium, storage in a corrosives cabinet would also be acceptable; however, it would need to be further segregated from the other incompatible corrosives by utilizing multiple cabinets or secondary containment.

It is best practice to minimize the quantities of hazardous chemicals on hand whenever possible. Minimization of stored chemicals is a key way to reduce the likelihood and severity of an incident involving said chemicals. Chemical storage limits, from various regulatory bodies and campus policy, are outlined on the EHS Maximum Allowable Quantities page. It is important to note that storage limitations, particularly based on fire code, often extend to large groupings of labs or even entire floors of buildings.

Flammable Storage Cabinets

Flammable storage cabinets are designed to meet specific requirements outlined by various standards such as OSHA, NFPA, IFC, and UL. They are specifically constructed to contain flammable materials and slow the spread of a fire towards the materials in the cabinet. The cabinets are typically red or yellow in color.

When purchasing a cabinet for your lab, look for a cabinet which is OSHA and NFPA approved (which will fulfill UL 1275) and has self-closing doors to comply with IFC. If you have an existing cabinet, it should be labeled if it meets any of these standards. Contact EHS if you need further information on your available storage cabinets.

Flammable storage cabinets are not required to be vented, and it is not recommended to do so in most cases. Improper venting can negate the fire protection provided by a cabinet.

Flammable storage cabinets can be free standing cabinets in the laboratory or built under the fume hood.

Corrosive Storage Cabinets

Corrosive cabinets must be constructed from corrosion-resistant materials like polyethylene or coated steel, feature a leak-proof spill sump, a secure locking mechanism, and be clearly labeled to identify their contents. The cabinets are typically blue in color. For safety and regulatory compliance, they should be equipped with spill-containing shelves and may require ventilation to a fume hood or local exhaust system, especially for volatile corrosives.

In laboratories with fume hoods, corrosive storage cabinets are often located below the hood or vented through it. If the lab lacks a fume hood, the cabinet can be vented to the laboratory exhaust system. For volatile corrosives like hydrochloric acid, venting is beneficial for removing hazards vapors.

Strong oxidizing agents like nitric acid or perchloric acid should be stored separately from other acids, ideally in their own cabinet or within secondary containment.

For more information about flammable liquids and corrosives, visit Specific Chemical Hazards.